Cost efficient loading

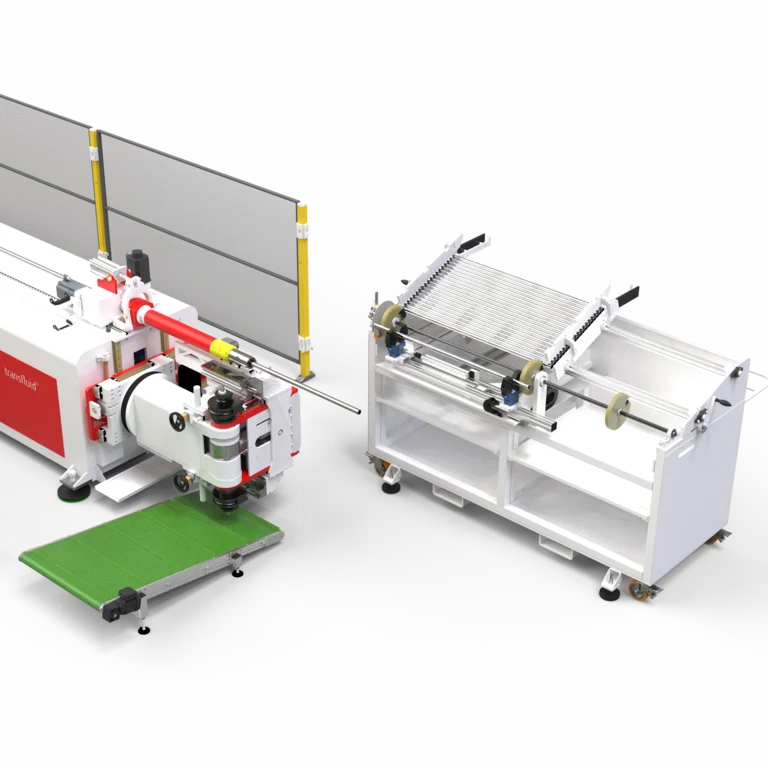

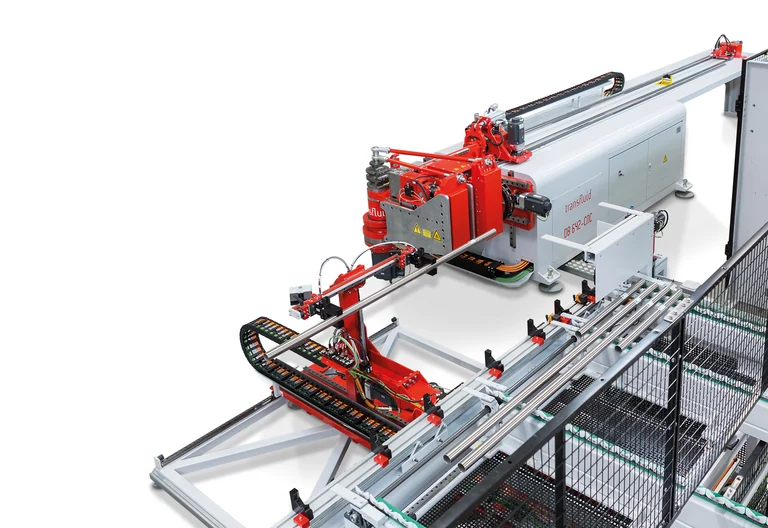

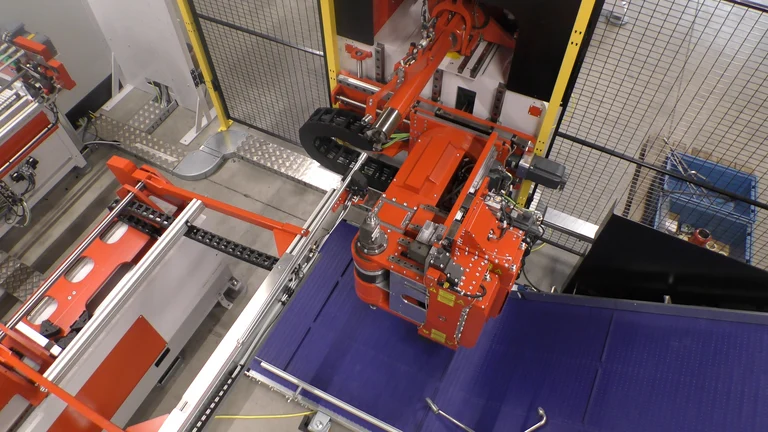

Simple and flexible. Transfluid offers a great variety of loading systems for different materials, tube diameters and tube lengths. We have developed a simple and more cost efficient loading unit specifically to add even greater flexibility to our CNC tube bending machine; it offers our clients the option of using the machine as a small production cell with automated unloading, for instance with a conveyor belt.

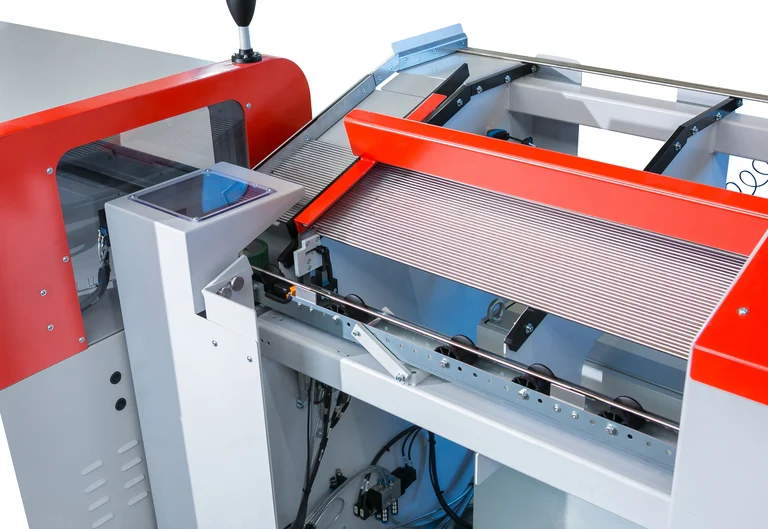

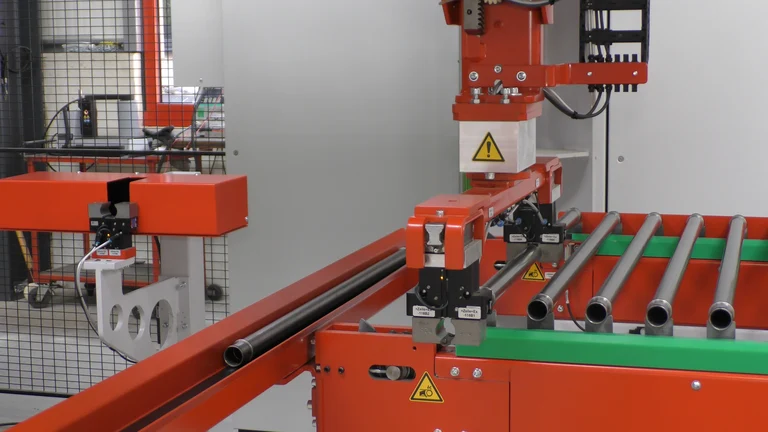

The feeding magazine is filled with the necessary number of units. The guiding rails can be adjusted quickly to fit the different tube lengths and diameters. The tube is transferred to the gripper and the machine and fed into the bending process.

The loading system can be equipped with various sensors, if the customer requests it, so that the loading can be controlled and monitored digitally. This is particularly useful in the production of different tube geometries for special projects or spare parts.