The solution for tube systems in the hydraulics sector

Premier bending and connection technology for ready to install hydraulic lines

transfluid® Reliable precise fit for safe hydraulic system

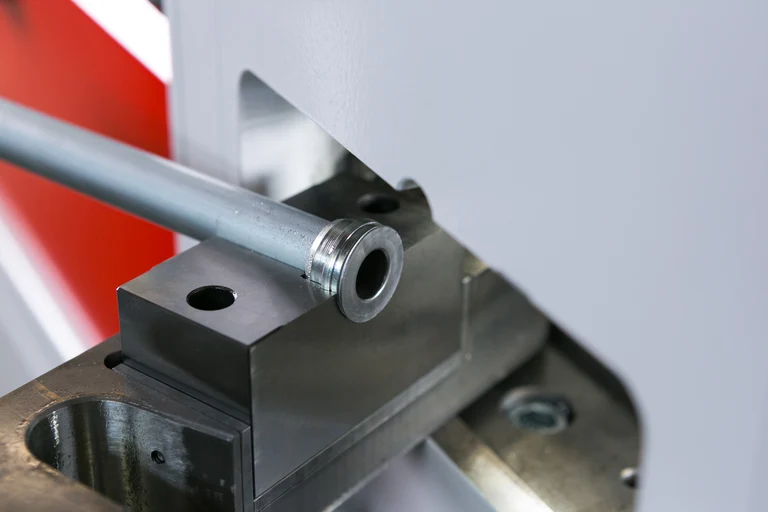

Hydraulic lines are integral to the efficient and safe operation of hydraulic systems. The connection technology used in these lines must demonstrate resilience and reliability to withstand high pressures and dynamic loads. With steadfast assurance, transfluid offers specialized machinery and techniques for a variety of threaded couplings, ensuring long-lasting and secure sealing. For over 35 years, the hydraulics industry has entrusted our solutions. Whether for mobile, manual production on-site, or flexible production systems, transfluid provides dependable solutions that inspire unwavering confidence. We are dedicated to delivering trustworthy and efficient solutions for all your hydraulic system requirements.

Forming variety and automatic bending for hydraulics

JIC, JIS BSP, BSPP, DIN, ORFS

Hydraulic piping, Connections, Manufacturing of hose end fittings

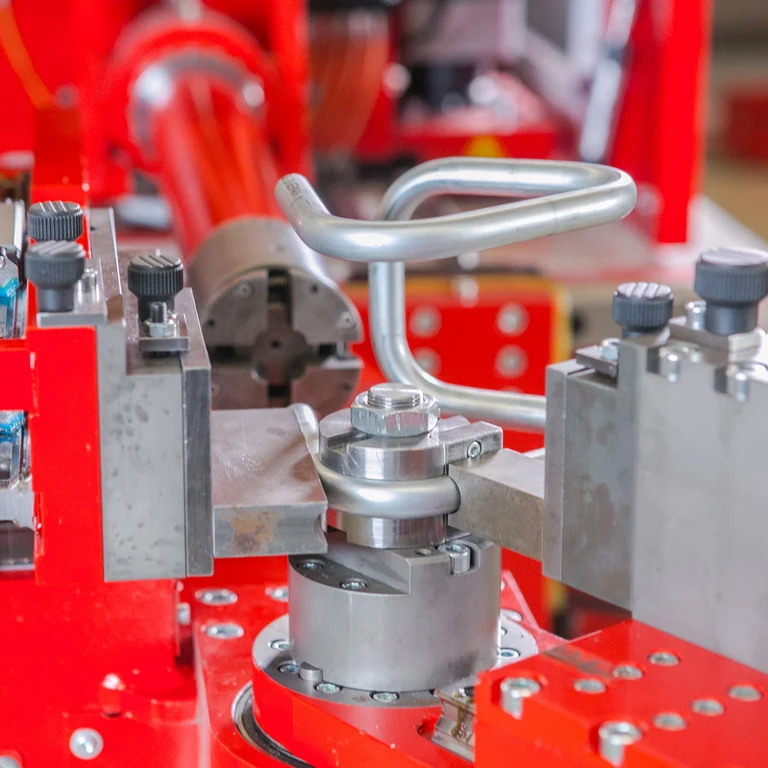

Special bending machines for fittings

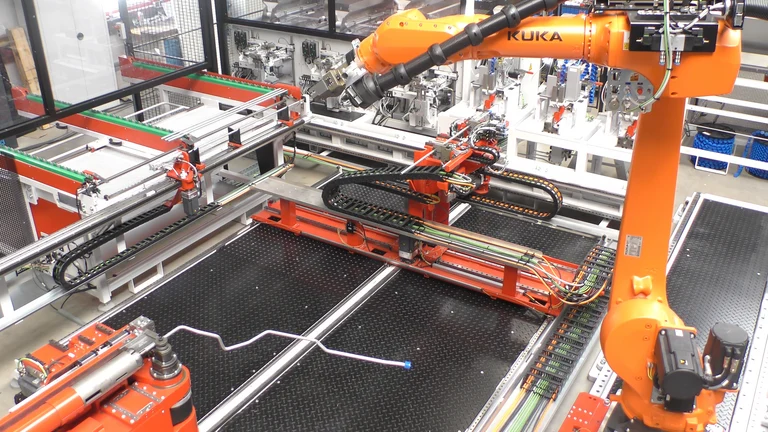

Assembly systems for sleeves, nuts and O-rings

Component marking and control systems

All common connection systems on the market can be processed

Powerful pipe shaping and bending technology create safe mobile hydraulics

The extreme demands imposed on construction vehicles require them to have precision-fit pipework and reliable joints and connections on their hydraulic drives, which tackle of lot of very heavy work. Specifically designed to meet these challenges, we have developed our compact CNC pipe-bending machines.

Hydraulics