More automation expertise for your tube processing.

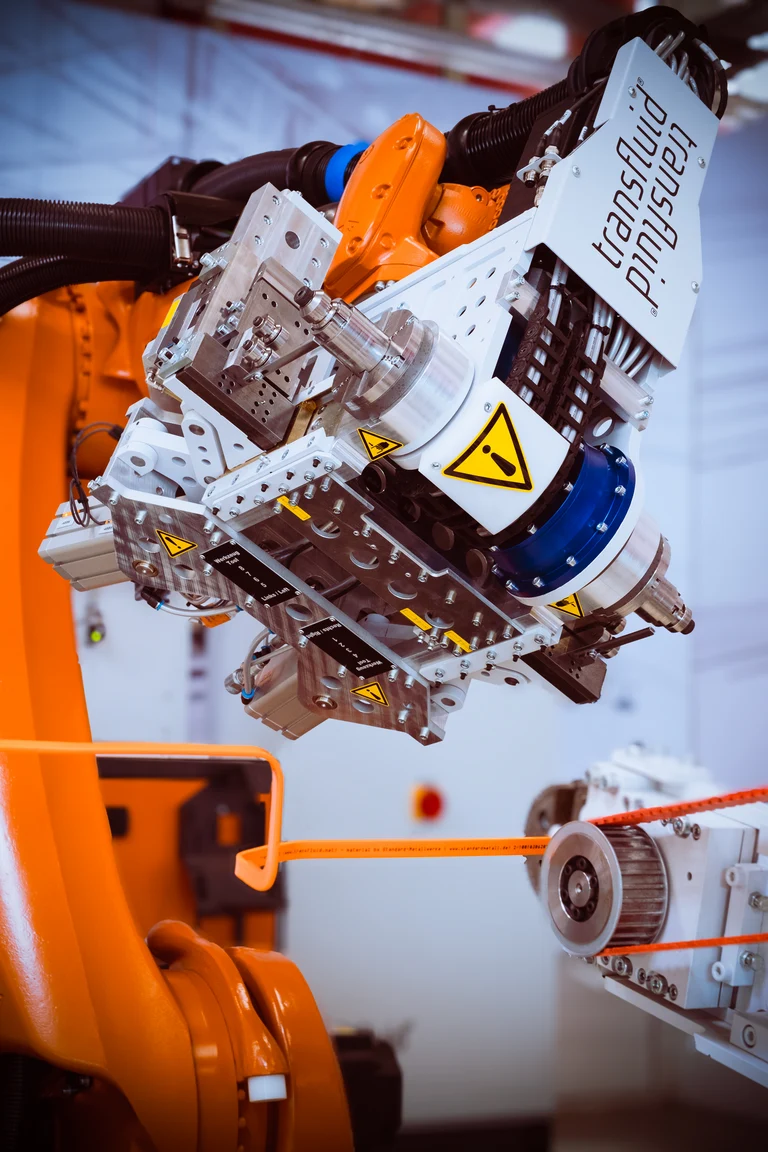

Higher efficiency and process reliability: Thanks to intelligent communication between robot and machine, and our proprietary robotic bending technology, fully automated production cells are created – with optimized cycle times and high repeat accuracy.

Future-ready technology platform: Benefit from access to state-of-the-art robot software, simulation tools, and digital KUKA services – combined with our proven expertise in tube bending and forming technology.

Joint development strength: Two strong partners combine their experience – from prototyping to series production – to realize customized solutions for demanding industries such as automotive, aerospace, hydraulics, HVAC, shipbuilding, and furniture manufacturing.

Worldwide support: Whether commissioning, training, or maintenance – KUKA’s global service and training network, together with our own service department, ensures reliable support worldwide.

This close cooperation underlines our commitment to providing complete automation solutions for tube processing from a single source – from intelligent stand-alone systems to fully connected production cells.

transfluid + KUKA – The Solution for Tubes meets Smart Automation.