transfluid® ROBOTIC BENDING TECHNOLOGY

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling.

transfluid® ROBOTIC BENDING TECHNOLOGY

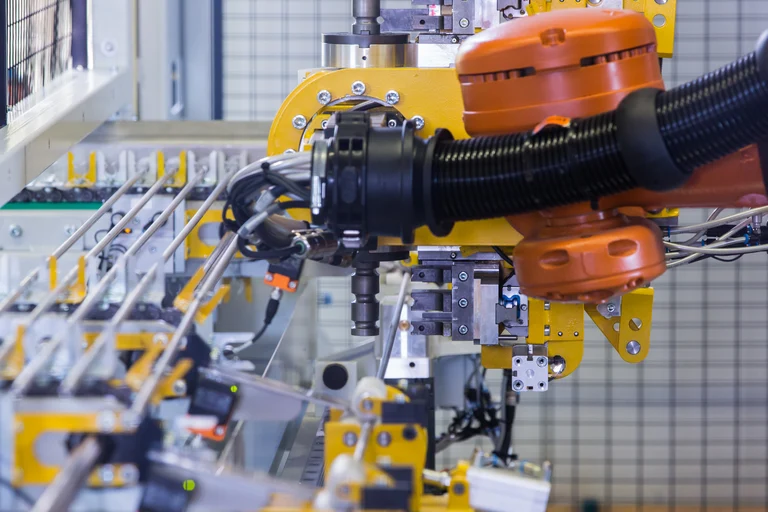

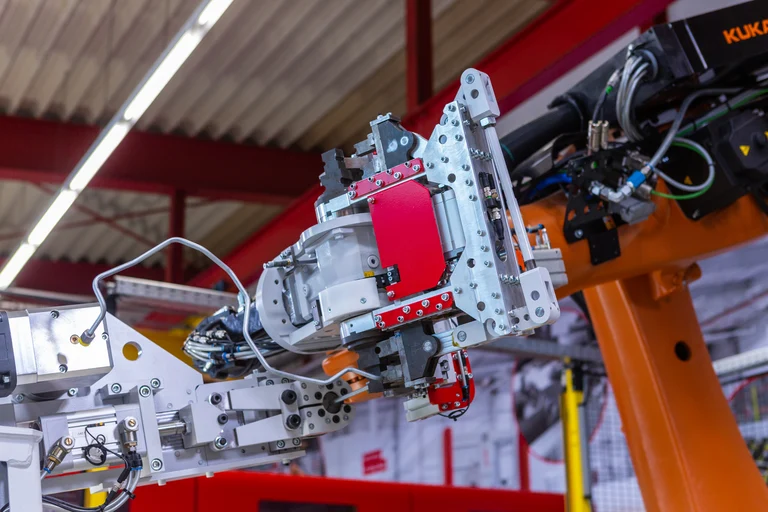

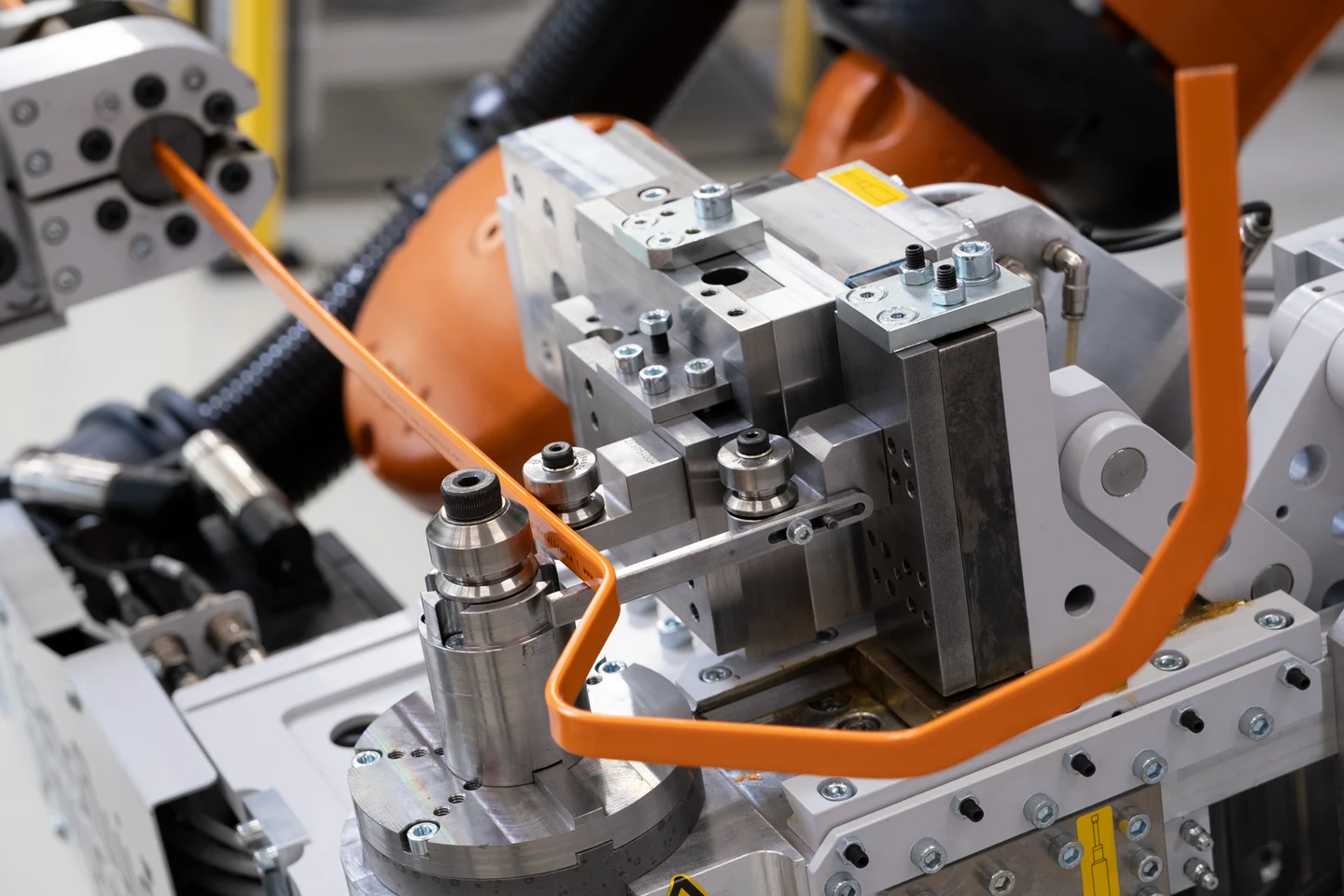

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped.

The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and add-on component can be done without any problems. The add-on components can be positioned automatically, if needed. A radii/plane changer with up to 3 tools per bending system is integrated to give maximum flexibility.

Machine sizes/tube sizes

| DB 622-ROBO-R/L | 6-22 mm Ø |

(copy 17)

Programming was yesterday

"Programming robots is a perfectly legitimate 'hurdle' for many companies. That's why we've made it simple and it's simply not necessary with our systems with robot benders," emphasizes Stefanie Flaeper. With the Transfluid systems, the coordinates are loaded from CAD and the robot knows how to bend. In addition, connections to measuring systems are possible and manual correction can be implemented very easily. This is because the robot is operated via a normal bending machine control system. This makes it possible to use the robot even more economically.

Not sure what you need?

We will find the right machine for your individual requirements. Our team of experts will be happy to advise you.