transfluid® Busbars & Solid-material

With transfluid®, you bring high end technology to your production. Our solutions, services and systems are attuned to what you need to produce on the world market level.

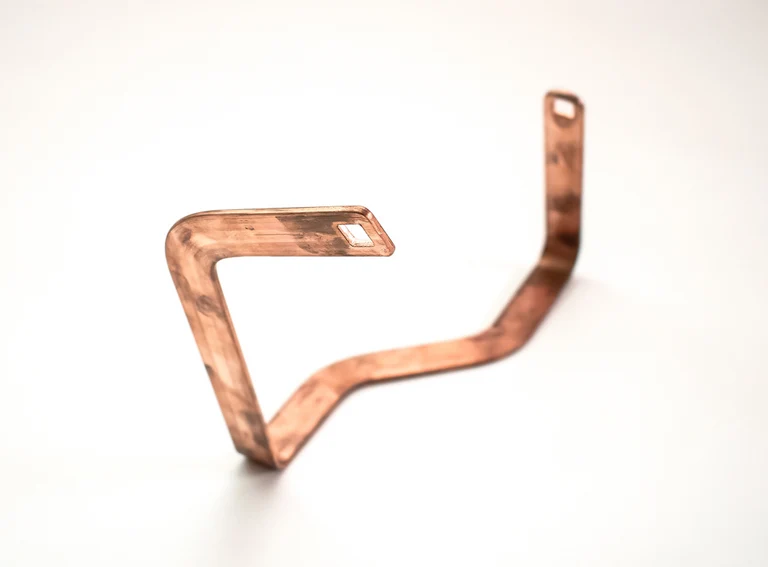

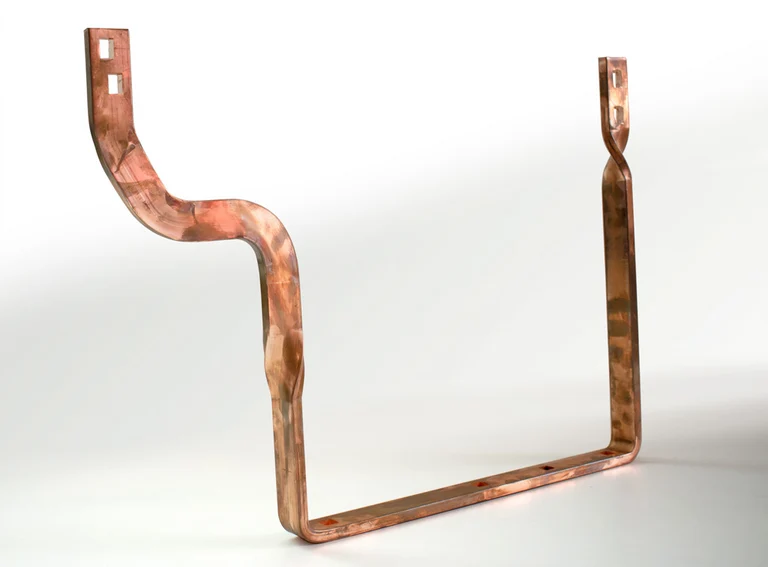

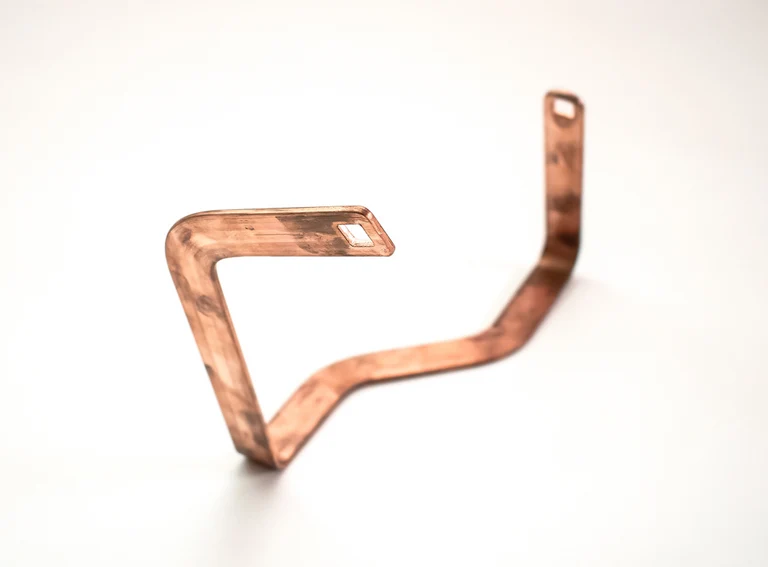

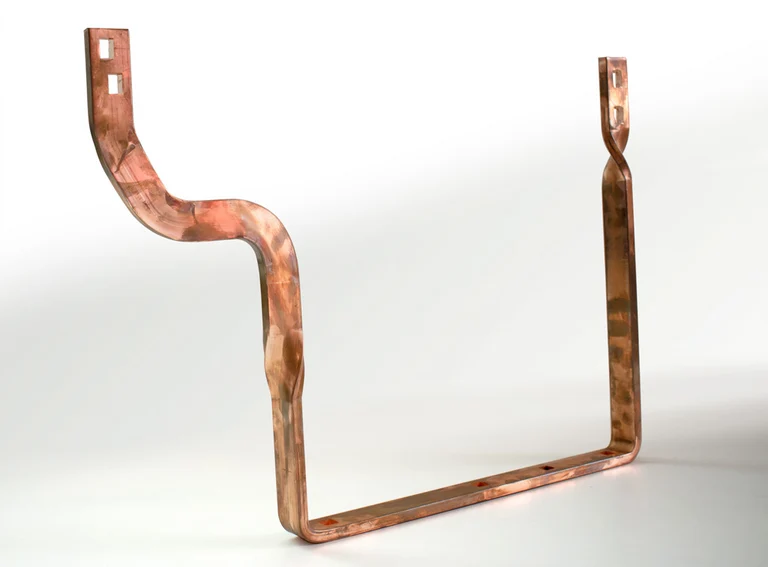

production samples

With transfluid®, you bring high end technology to your production. Our solutions, services and systems are attuned to what you need to produce on the world market level.

production samples