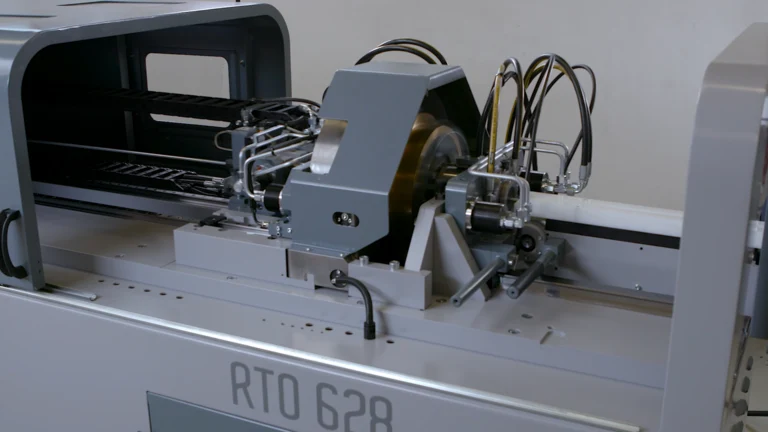

transfluid® t cut TYPE RTO

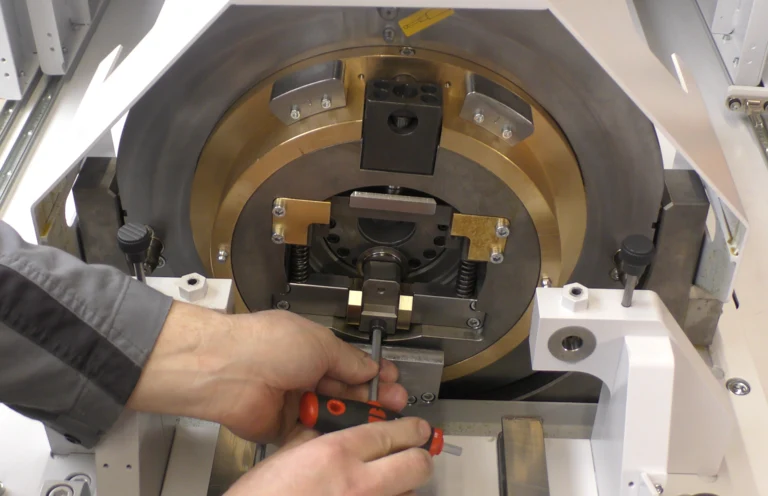

Created for precision.

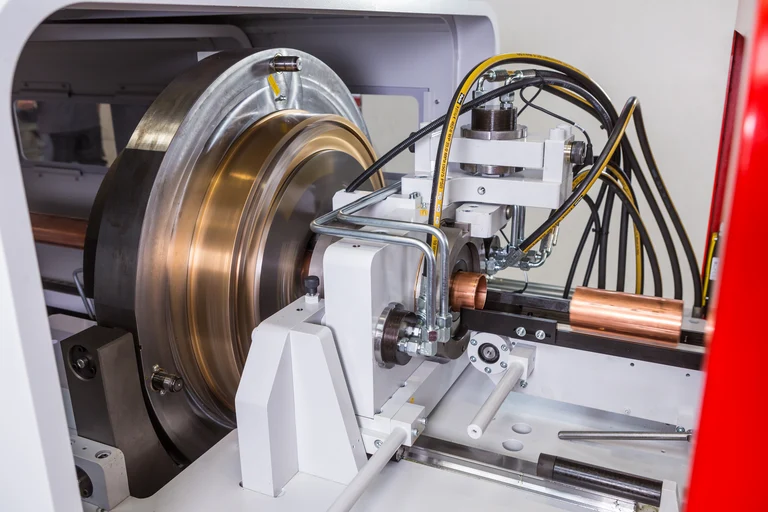

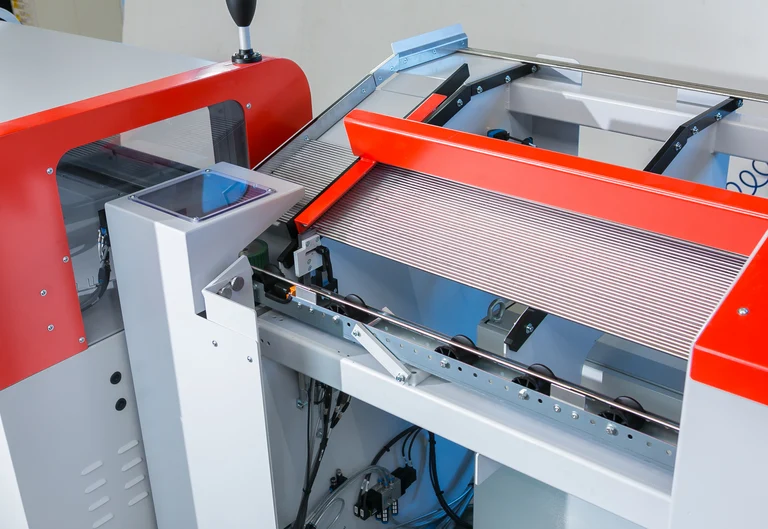

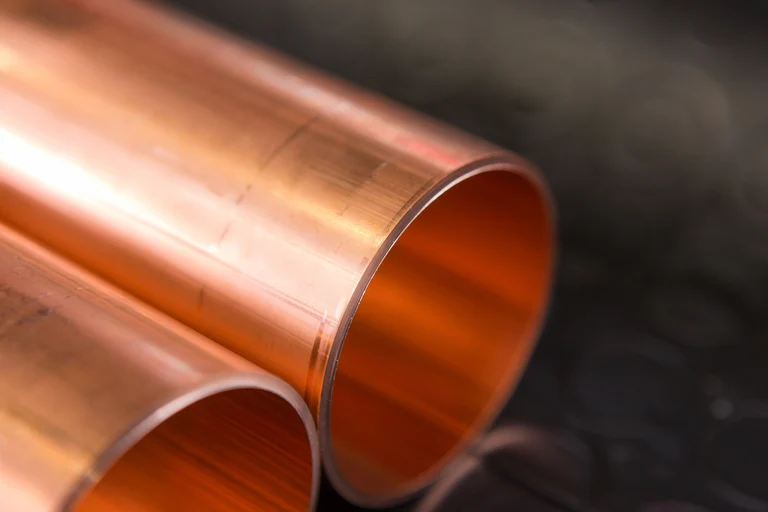

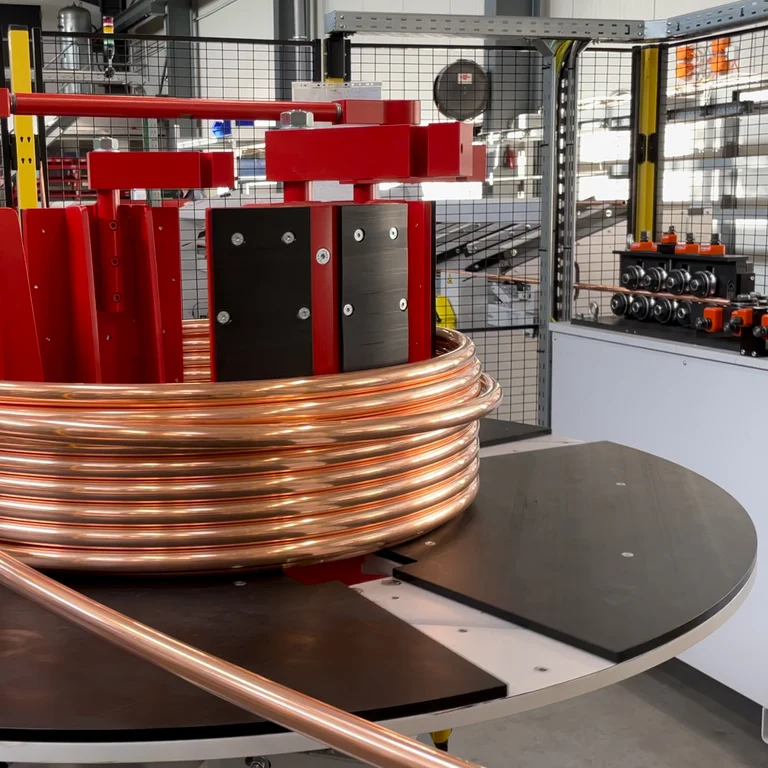

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money.

Technical specifications:

- Separation efficiency: max. Ø 30 x 3 for stainless steel tubes

- Shortest separation length: - 25 mm (without pull apart) - 55 mm (with pull apart)

- Remaining length: 110 mm

- Separation efficiency: up to 2,000 pcs per hour

PERFECT CUTS WITH THE GREATEST PRECISION

All transfluid machines deliver the highest cut quality and the workpieces can be processed without any further steps.

The right machine for your task

RTO CUTTING MACHINES

| Max. capacity | 6-28 mm |

| Wall thickness | 2,5 mm |

| Shortest cutting lenght (pull apart) | 53,34 mm |

| Shortest cutting lenght (through cut) | 25,4 mm |

| Cycle time adjustable | 2.2 - 8.0 sec. |

| Power | 7 kW |

| Weight | 1700 kg |

| L x W x H | 2800 x 1040 x 1600 mm |

| Max. capacity | 6 - 50 mm |

| Wall thickness | 2,4 mm |

| Shortest cutting lenght (pull apart) | 53,34 mm |

| Shortest cutting lenght (through cut) | 32,9 mm |

| Cycle time adjustable | 2.2 - 8.0 sec. |

| Power | 7 kW |

| Weight | 1700 kg |

| L x W x H | 2800 x 1040 x 1600 mm |

| Max. capacity | 20 - 80 mm |

| Wall thickness | 3 mm |

| Shortest cutting lenght (pull apart) | 100 mm |

| Shortest cutting lenght (through cut) | 70 mm |

| Cycle time adjustable | 5 - 10 sec. |

| Power | 10 kW |

| Weight | 3000 kg |

| L x W x H | 3810 x 1400 x 1600 mm |

| Max. capacity | 20 - 100 mm |

| Wall thickness | 3 mm |

| Shortest cutting lenght (pull apart) | 100 mm |

| Shortest cutting lenght (through cut) | 70 mm |

| Cycle time adjustable | 5 - 10 sec. |

| Power | 10 kW |

| Weight | 4091 kg |

| L x W x H | 3100 x 1300 x 1650 mm |

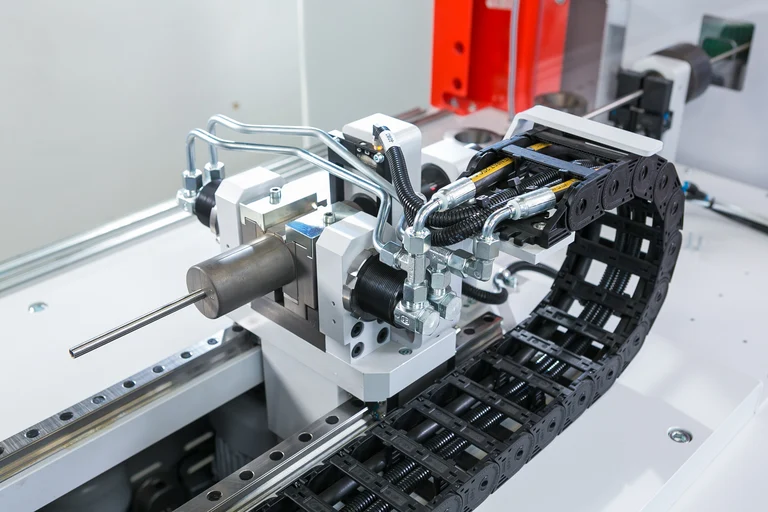

PREPARED FOR INTEGRATION INTO PRODUCTION CELLS

Whether as a stand-alone machine or as production cell, the t cut machines are above the rest thanks to the easy operation and accurate results!

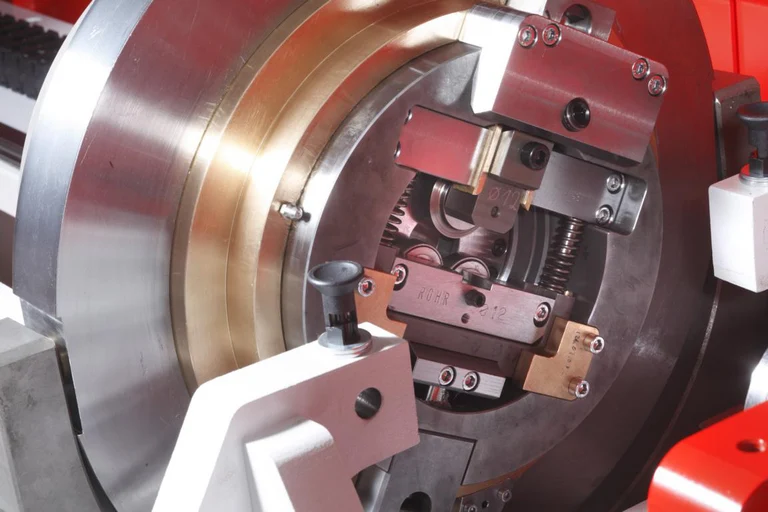

A COMPELLING OPTION FOR CLEAN CUTTING RESULTS

All transfluid machines deliver the highest cut quality and the workpieces can be processed without any further steps.

Catalog Download

transfluid® offers the complete package for the production of tubing.

Download our new catalogue.