NEW FROM STOCK

Actual available stock & used machines

When time is of the essence!

We always have a large selection of immediately available new machines, demonstration machines in mint condition and used machines in stock. Benefit from attractive offers for top-equipped-machines:

- All stock machines are immediately available and ready for use

- Demonstration machines with low operating hours

- Used machines in top condition

Get in contact with our experts.

Are you interested in one of our machines?

Get in touch with us – we’ll be pleased to prepare a non-binding quotation for you.

If you require additional equipment options or accessories, please don’t hesitate to contact us.

Lukas Weingärtner

Office: +49 2972 / 97 15 785

t bend BENDING MACHINES

Highly efficient CNC bending technology for small and big bending tasks with the greatest precision.

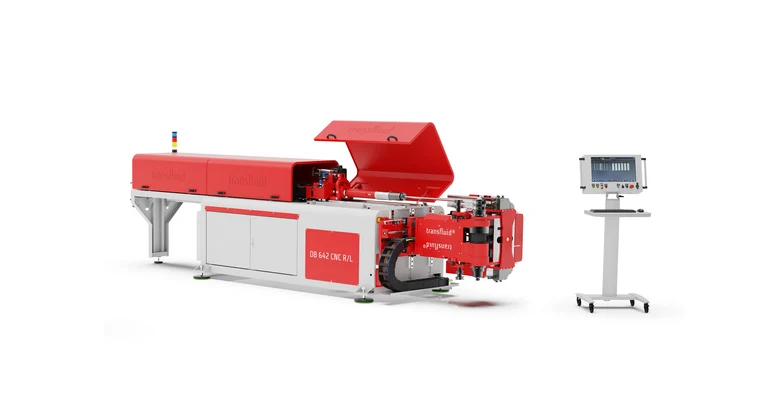

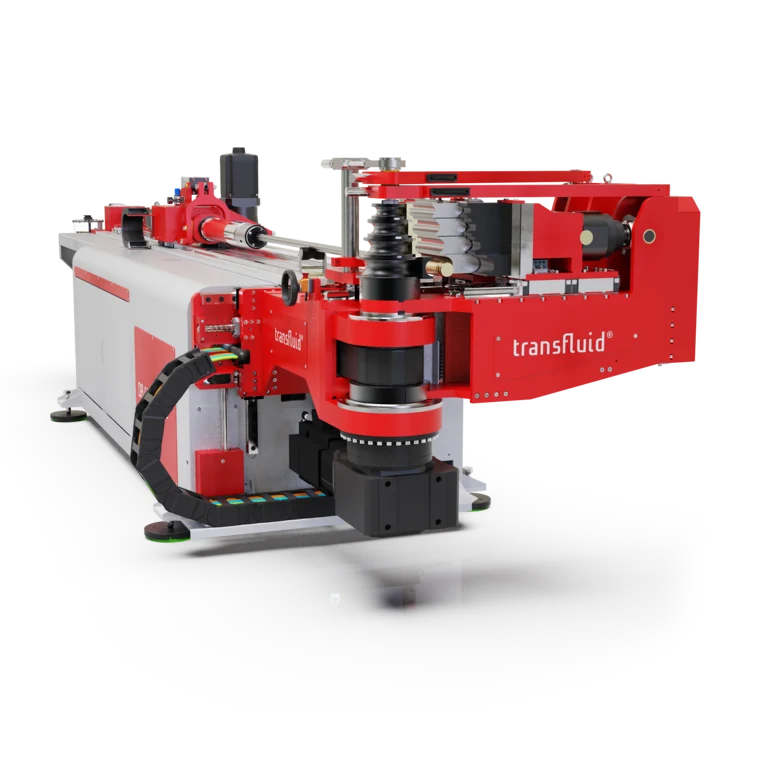

CNC -MANDREL BENDING MACHINE- TYPE R/L

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. For pipes with diameters from 1/4" to 2 3/8".

| Model | Tube-ø | Max. radius |

|---|---|---|

| DB 622-CNC-R/L | 6 – 22 mm | 66 mm |

| DB 642-CNC-R/L | 6 – 42 mm | 90 mm |

| DB 2060-CNC-R/L | 20 – 60 mm | 180 mm |

CNC - MANDREL BENDING MACHINE - TYPE VE

The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For pipes with diameters from 1/4" to 6".

| Model | Tube-ø | Max. radius |

|---|---|---|

| DB 650-CNC-VE | 6 – 50,8 mm | 150 mm |

MANDREL BENDING MACHINE - TYPE K

Our compact mandrel bending machines are operated fully with hydraulics. Perfect bend quality with tight bending radii, from 1.5xD.

| Model | Tube-ø | Max. radius |

|---|---|---|

| DB 642-K | 6 – 42 mm | 105 mm |

| DB 2076-K | 20 – 76,1 mm | 150 mm |

t form TUBE FORMING MACHINES

Tube forming machines for short production times and outstanding results.

AXIAL FORMING MACHINE - TYPE REB

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements.

| Model | Tube-ø | Forming length | Cycle time |

|---|---|---|---|

| REB 420 | 4 – 20 mm | 60 mm | 2 – 3 sec. |

| REB 632 | 6 – 32 mm | 80 mm | 2 – 3 sec. |

| REB 645 | 6 – 45 mm | 90 mm | 3 – 5 sec. |

| REB 660 | 6 – 60 mm | 180 mm | 5 – 8 sec. |

ROLLFORMING MACHINE - TYPE SRM

Many forming options with one type of machine: forming, cutting, cutting after bending and threading. Our Type SRM forming machines are ideally suited for the production of challenging contours for sealing elements and for the generation of extremely good surfaces.

| Model | Tube-ø | Wall thickness max | Cycle time |

|---|---|---|---|

| SRM 622 | 4 – 22 mm | 1,0 mm | 4 – 10 sec. |

| SRM 1565 | 15 – 65 mm | 1,5 mm | 8 – 14 sec. |

COMBINATION MACHINE - TYPE REB/SRM

Highly demanding forming geometries in one work sequence: in our combination machines we have combined the benefits of axial and rollforming in one single system. Further processing step can be integrated without any problems.

| Model | Tube-ø | Forming length | Cycle time |

|---|---|---|---|

| REB/SRM 632 | 6 – 32 mm | 80 mm | 2 – 3 sec. |

| REB/SRM 645 | 6 – 45 mm | 90 mm | 3 – 5 sec. |

ROLLFORMING MACHINE - TYPE UMR

The type UMR tube forming machine and its special tumble method and contoured flaring mandrels guarantee high quality as standard. It produces perfect and mirror-like sealing surfaces when forming tubes up to a diameter of 325 mm.

| Model | Tube-ø | Wall thickness max | Cycle time |

|---|---|---|---|

| UMR 628 | 6 – 28 mm | 2,5 mm | 4 – 10 sec. |

| UMR 642 | 6 – 42 mm | 4,0 mm | 4 – 15 sec. |

t cut - CHIPLESS ORBITAL CUTTING MACHINES

transfluid machines deliver the highest cut quality and the workpieces can be processed without any further steps.

CHIPLESS ORBITAL CUTTING MACHINE - TYPE RTO

Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money.

| Model | Tube-ø | Wall thickness | Cycle time |

|---|---|---|---|

| RTO 628 | 6 – 28 mm | 2,0 mm | 2,2 – 8,0 sec |