T BEND FULLY AUTOMATED CNC TUBE BENDING MACHINES:

SATISFY EVEN THE TOUGHEST REQUIREMENTS.

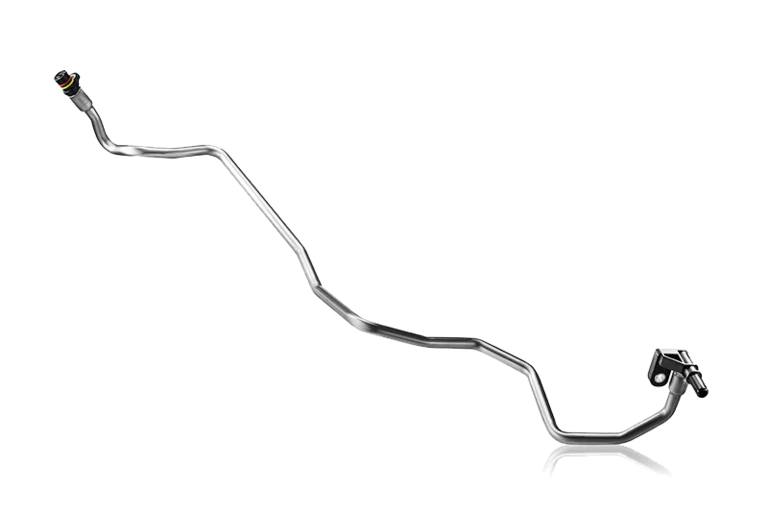

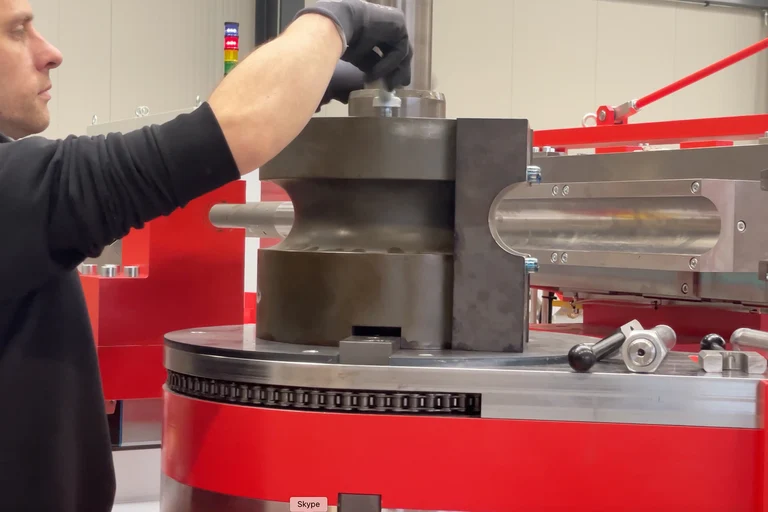

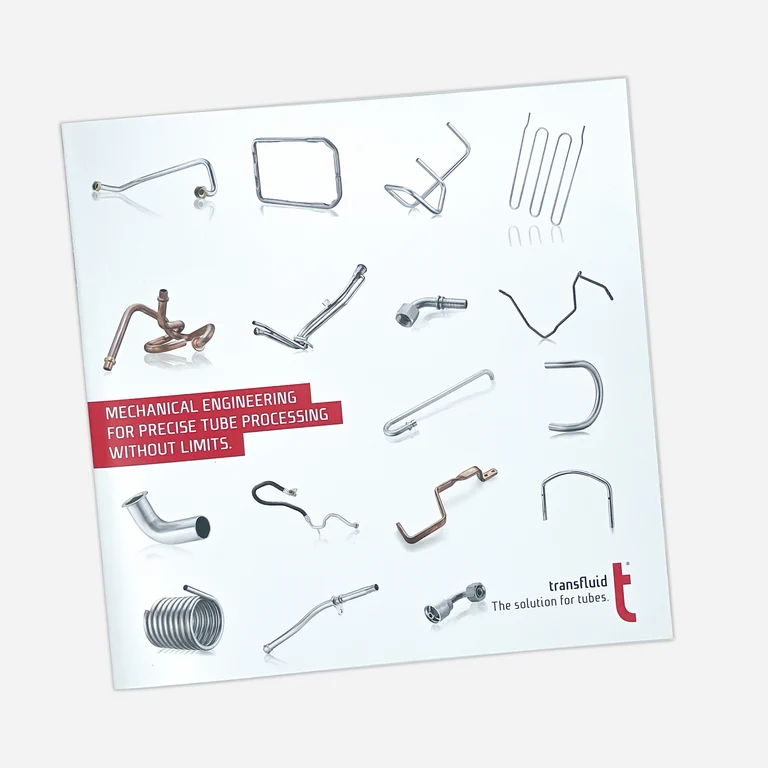

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements.

Not sure what you need?

We will find the right machine for your individual requirements. Our team of experts will be happy to advise you.

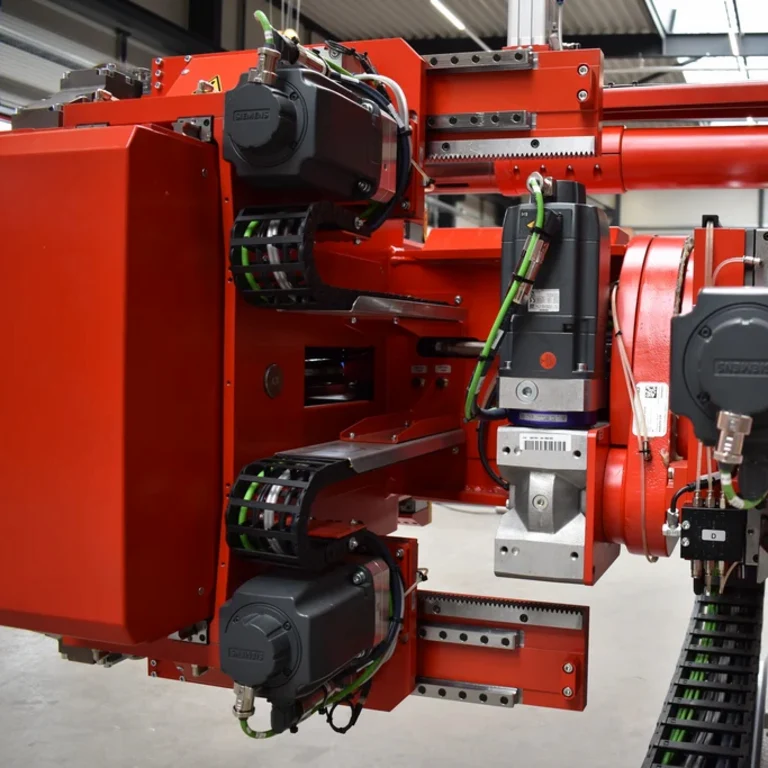

t bend tube bending systems with servoelectric and servohydraulic controls

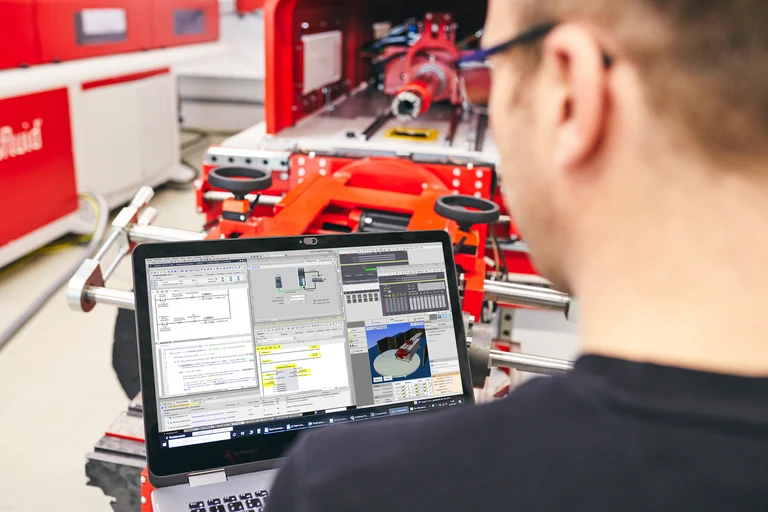

We develop high-performance versions of bending systems, so you can set up your manufacturing processes in an innovative and forward-looking way. Our transfluid tube bending technology is available to you to achieve perfect results, with all possible options, including fully automated solutions. Our smart t project software creates safe processes with clever simulations.

Catalog Download

transfluid® offers the complete package for the production of tubing.

Download our new catalogue.

Tube bending machines and excellent service

Gives service technicians remote access to machine controls.

The excellent 24-hour after-sales service from transfluid® also guarantees particular sustainability of our solutions.

Flexible, fast and comprehensive spare parts supply through spare parts warehouse in the USA.